Whether you have a passion for design or you are a seasoned professional, an industrial designer career is a great choice. Industrial designers work in collaboration with engineers to develop products. In addition to designing, industrial designers also conduct investigations into materials and perform market research. These designers often present their designs and ideas to sales staff and decision-makers. They can work as freelancers or full-time in the industry.

Designers in industry create physical prototypes for their designs. These prototypes can vary depending on the type of design. They may be created with different software and tools for computer-aided manufacturing (CAD). They are used to assess their design and function. The prototypes are also used to create a visual representation for the product.

Engineers often collaborate with industrial designers to develop prototypes. They use software like SolidWorks or AutoCAD to design the prototypes. They also meet with their clients to sketch their plans. They must be creative and have excellent analytical skills.

Industrial designers may also have to travel to the manufacturing or testing facilities of their clients. Clients may also require them to meet on weekends and evenings.

Although industrial designers are often employed in an office, they also have the option to work freelance. Industrial designers have the opportunity to work abroad. If you want to work abroad, you will need to pass international exams and communicate in English. Solid education is also a must. The work of industrial designers abroad can last up to 3 years.

Bachelor's degrees are required for industrial designers. Employers often prefer candidates with graphic design skills. Industrial designers may also want to consider enrolling in a CAD bootcamp. These classes are typically free and can help to teach you the necessary tools. You can also become a certified professional designer after completing these classes. CAD certification is recognized by industrial design firms.

Designers in industrial design need to create functional and attractive designs for products. They can design many items, such medical equipment or consumer electronics. Designers in industrial design must be as knowledgeable as possible about the product that they are creating. Industrial designers must be proficient in problem-solving and writing. They are also responsible for reducing production costs. They are also extremely creative and have a passion about designing products.

A resume for industrial designers should focus on their personal goals. They should also include information about their previous work experiences and the company's needs. A portfolio of their past work should also be included. This portfolio could include projects created during internships or classes.

For prototypes and concept development, industrial designers often collaborate closely with engineers and manufacturing experts. They may also work with marketing experts to promote their products. They present their designs to sales staff, decision makers, and the general population. They may also be asked to travel to the testing and manufacturing sites of their clients. They might have to meet clients and sales people on weekends or nights.

FAQ

What are the products of logistics?

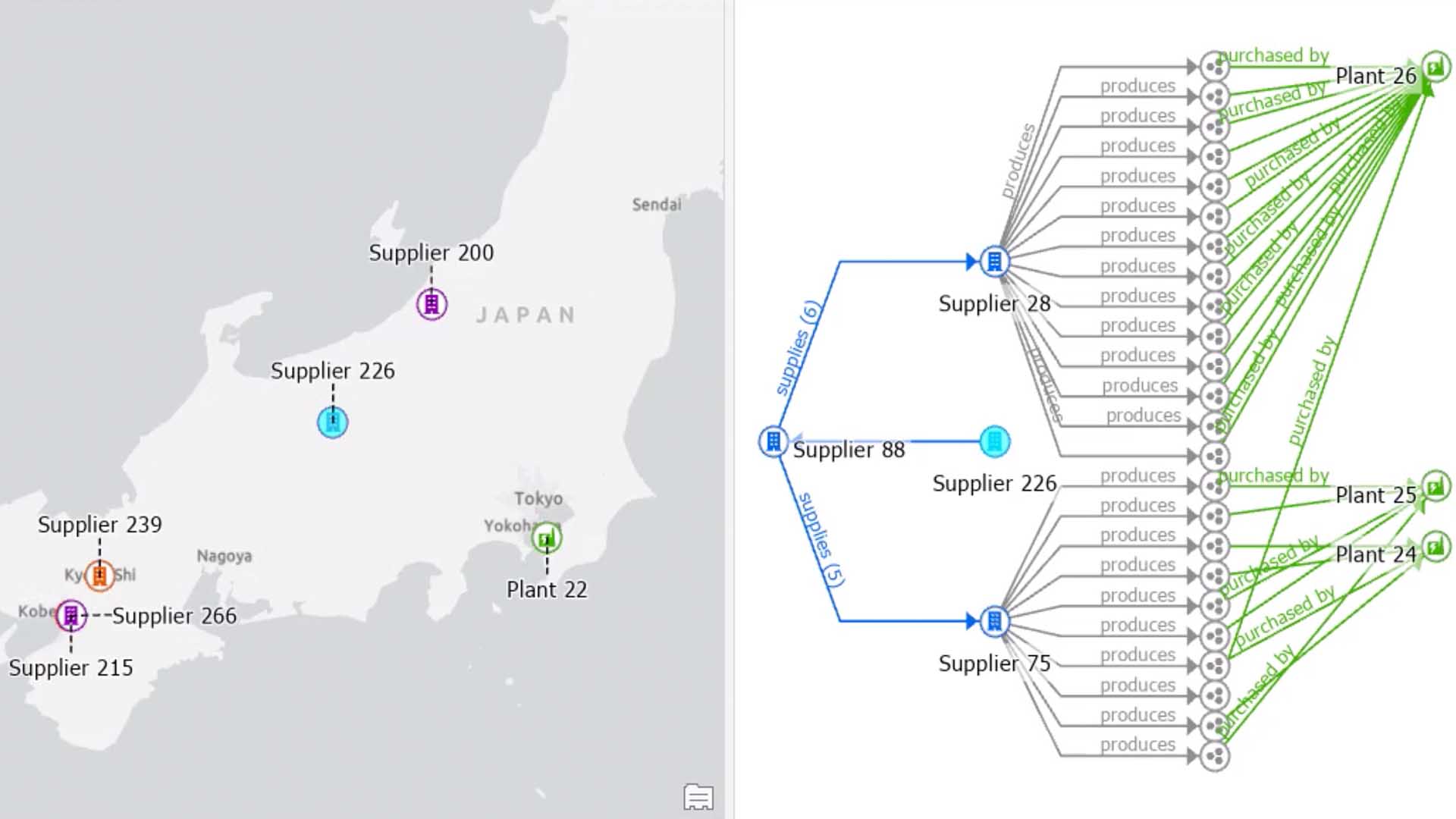

Logistics refers to the movement of goods from one place to another.

They include all aspects of transport, including packaging, loading, transporting, unloading, storing, warehousing, inventory management, customer service, distribution, returns, and recycling.

Logisticians ensure the product reaches its destination in the most efficient manner. Logisticians assist companies in managing their supply chains by providing information such as demand forecasts, stock levels and production schedules.

They keep track and monitor the transit of shipments, maintain quality standards, order replenishment and inventories, coordinate with suppliers, vendors, and provide support for sales and marketing.

What is the difference between manufacturing and logistics

Manufacturing is the production of goods using raw materials. Logistics manages all aspects of the supply chain, including procurement, production planning and distribution, inventory control, transportation, customer service, and transport. Sometimes manufacturing and logistics are combined to refer to a wider term that includes both the process of creating products as well as their delivery to customers.

What is the importance of logistics in manufacturing?

Logistics are an integral part any business. They enable you to achieve outstanding results by helping manage product flow from raw materials through to finished goods.

Logistics play a key role in reducing expenses and increasing efficiency.

What do you mean by warehouse?

A warehouse, or storage facility, is where goods are stored prior to being sold. It can be either an indoor or outdoor space. In some cases it could be both indoors and outdoors.

What is production planning?

Production Planning includes planning for all aspects related to production. This document ensures that everything is prepared and available when you are ready for shooting. This document should include information about how to achieve the best results on-set. This includes location information, crew details, equipment specifications, and casting lists.

The first step in filming is to define what you want. You may have decided where to shoot or even specific locations you want to use. Once you have identified your locations and scenes it's time to begin figuring out what elements you will need for each one. You might decide you need a car, but not sure what make or model. In this case, you could start looking up cars online to find out what models are available and then narrow your choices by choosing between different makes and models.

After you have selected the car you want, you can begin to think about additional features. Are you looking for people to sit in the front seats? Maybe you need someone to move around in the back. You may want to change the interior's color from black or white. These questions will help determine the look and feel you want for your car. The type of shots that you are looking for is another thing to consider. What type of shots will you choose? Maybe you want to show your engine or the steering wheel. These things will help you to identify the car that you are looking for.

Once you have established all the details, you can create a schedule. You will know when you should start and when you should finish shooting. A schedule for each day will detail when you should arrive at the location and when you need leave. Everyone will know what they need and when. Book extra staff ahead of time if you need them. You don't want to hire someone who won't show up because he didn't know.

Also, consider how many days you will be filming your schedule. Some projects are quick and easy, while others take weeks. It is important to consider whether you require more than one photo per day when you create your schedule. Multiple shots at the same location can increase costs and make it more difficult to complete. If you are unsure if you need multiple takes, it is better to err on the side of caution and shoot fewer takes rather than risk wasting money.

Budgeting is another crucial aspect of production plan. Setting a realistic budget is essential as it will allow you to work within your means. If you have to reduce your budget due to unexpected circumstances, you can always lower it later. It is important to not overestimate how much you will spend. You'll end up with less money after paying for other things if the cost is underestimated.

Production planning is a complicated process. But once you understand how everything works together, it becomes much easier to plan future project.

Statistics

- (2:04) MTO is a production technique wherein products are customized according to customer specifications, and production only starts after an order is received. (oracle.com)

- [54][55] These are the top 50 countries by the total value of manufacturing output in US dollars for its noted year according to World Bank.[56] (en.wikipedia.org)

- You can multiply the result by 100 to get the total percent of monthly overhead. (investopedia.com)

- According to a Statista study, U.S. businesses spent $1.63 trillion on logistics in 2019, moving goods from origin to end user through various supply chain network segments. (netsuite.com)

- Job #1 is delivering the ordered product according to specifications: color, size, brand, and quantity. (netsuite.com)

External Links

How To

Six Sigma and Manufacturing

Six Sigma refers to "the application and control of statistical processes (SPC) techniques in order to achieve continuous improvement." Motorola's Quality Improvement Department developed it at their Tokyo plant in Japan in 1986. Six Sigma's basic concept is to improve quality and eliminate defects through standardization. Many companies have adopted this method in recent years. They believe there is no such thing a perfect product or service. The main goal of Six Sigma is to reduce variation from the mean value of production. This means that if you take a sample of your product, then measure its performance against the average, you can find out what percentage of the time the process deviates from the norm. If it is too large, it means that there are problems.

Understanding the nature of variability in your business is the first step to Six Sigma. Once you've understood that, you'll want to identify sources of variation. Also, you will need to identify the sources of variation. Random variations occur when people make mistakes; systematic ones are caused by factors outside the process itself. If you make widgets and some of them end up on the assembly line, then those are considered random variations. However, if you notice that every time you assemble a widget, it always falls apart at exactly the same place, then that would be a systematic problem.

Once you've identified where the problems lie, you'll want to design solutions to eliminate those problems. You might need to change the way you work or completely redesign the process. Once you have implemented the changes, it is important to test them again to ensure they work. If they didn't work, then you'll need to go back to the drawing board and come up with another plan.