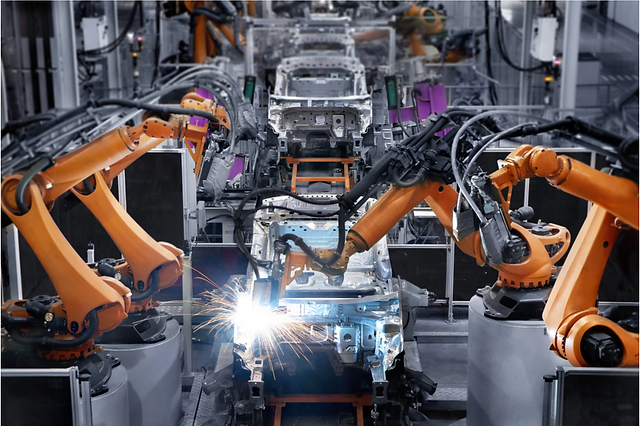

A basic understanding of Articulated-arm and Anthropomorphic robotic arms is essential for their successful operation. This article will provide an overview of the differences between the two types, as well as the Mechanical or Sensor units in an arm-robot. To better understand the differences we will look at what each can do and how it can aid our daily lives. These are important design considerations. It is important to consider the weight and size of the component that will be handled as well as the required gripper. Also, the attachment's weight must be equal to or less than the component to be grasped. Additionally, it is important to consider whether an attachment's center of mass is far away from the component, which could result in a higher payload.

Robots with articulated arms

The versatility of Articulated-arm robots is impressive. Each six-axis robot has a flexible arm that is similar to a human's arm. It can rotate around its base and bend in the middle like an elbow. An Articulated Arm robot's wrist can move in an arc like a human's and it can also rotate its hand. This allows the robot's grasp of objects at any part of the component.

Anthropomorphic robotic arms

Anthropomorphic robot arms are robotic arms that mimic human arm movements. These robotic arms are designed to handle different objects. They employ tele-replication human motion, which allows the operator to execute his motion patterns. These robots have been successfully tested in various applications. Researchers developed a method to interpret the movements of the human operator, and then implement them into the robot arm.

Machine unit for arm robots

Many functions can be performed by the mechanical arm robot's unit. Robotic wrists allow the end-effector to be placed on a workpiece. The wrist has two rotary joints. One allows for the end effector to turn and the second to move in one direction. Both the wrists and the end effector have different degrees. Combining these units allows you to move parts on pallets.

Sensor unit in arm robots

A sensor unit inside an arm robot's robotic arm is designed to detect changes in human body heat. This sensor is placed on the robotic arm's gripper end, where it can contact a temperature-measurement object. Once it detects changes of temperature, it sends a signal through the robot's base to the STM32 single-chip microcomputer. The STM32 controls the actions of the robot, and when it senses that the temperature has reached dangerous levels, the STM32 sends an alert to the operator. During normal operations, it won't be necessary to interrupt the robot.

Cost to join an arm robotics robot

A robotic arm can be expensive if you are looking to make one. There are many factors that affect the cost of an arm robotic arm. These include the size and number of axes used, safety components and end-of-arm tooling. The larger the robot, the higher the price will be, as will the additional peripherals and tooling you need. Apart from the robot's size, an additional factor that affects cost is its application. A larger robot has a greater payload and can achieve greater reach, but the added cost is usually offset by reduced cost of safety features.

FAQ

What is the difference between manufacturing and logistics

Manufacturing is the act of producing goods from raw materials using machines and processes. Logistics covers all aspects involved in managing supply chains, including procurement and production planning. Manufacturing and logistics can often be grouped together to describe a larger term that covers both the creation of products, and the delivery of them to customers.

How can manufacturing overproduction be reduced?

Better inventory management is key to reducing excess production. This would reduce the amount of time spent on unnecessary activities such as purchasing, storing, and maintaining excess stock. By doing this, we could free up resources for other productive tasks.

This can be done by using a Kanban system. A Kanbanboard is a visual tool that allows you to keep track of the work being done. Work items are moved through various states to reach their destination in a Kanban system. Each state is assigned a different priority.

As an example, if work is progressing from one stage of the process to another, then the current task is complete and can be transferred to the next. However, if a task is still at the beginning stages, it will remain so until it reaches the end of the process.

This allows work to move forward and ensures that no work is missed. Managers can view the Kanban board to see how much work they have done. This allows them to adjust their workflows based on real-time information.

Lean manufacturing can also be used to reduce inventory levels. Lean manufacturing is about eliminating waste from all stages of the production process. Waste includes anything that does not add value to the product. These are some of the most common types.

-

Overproduction

-

Inventory

-

Unnecessary packaging

-

Exceed materials

Manufacturers can reduce their costs and improve their efficiency by using these ideas.

What is the job of a production plan?

A production planner makes sure all project elements are delivered on schedule, within budget, as well as within the agreed scope. A production planner ensures that the service and product meet the client's expectations.

Statistics

- Job #1 is delivering the ordered product according to specifications: color, size, brand, and quantity. (netsuite.com)

- According to a Statista study, U.S. businesses spent $1.63 trillion on logistics in 2019, moving goods from origin to end user through various supply chain network segments. (netsuite.com)

- According to the United Nations Industrial Development Organization (UNIDO), China is the top manufacturer worldwide by 2019 output, producing 28.7% of the total global manufacturing output, followed by the United States, Japan, Germany, and India.[52][53] (en.wikipedia.org)

- [54][55] These are the top 50 countries by the total value of manufacturing output in US dollars for its noted year according to World Bank.[56] (en.wikipedia.org)

- In 2021, an estimated 12.1 million Americans work in the manufacturing sector.6 (investopedia.com)

External Links

How To

How to use Lean Manufacturing in the production of goods

Lean manufacturing is a management system that aims at increasing efficiency and reducing waste. It was developed in Japan during the 1970s and 1980s by Taiichi Ohno, who received the Toyota Production System (TPS) award from TPS founder Kanji Toyoda. The first book published on lean manufacturing was titled "The Machine That Changed the World" written by Michael L. Watkins and published in 1990.

Lean manufacturing can be described as a set or principles that are used to improve quality, speed and cost of products or services. It is about eliminating defects and waste from all stages of the value stream. Lean manufacturing is called just-in-time (JIT), zero defect, total productive maintenance (TPM), or 5S. Lean manufacturing emphasizes reducing non-value-added activities like inspection, rework and waiting.

In addition to improving product quality and reducing costs, lean manufacturing helps companies achieve their goals faster and reduces employee turnover. Lean manufacturing has been deemed one of the best ways to manage the entire value-chain, including customers, distributors as well retailers and employees. Lean manufacturing can be found in many industries. Toyota's philosophy is the foundation of its success in automotives, electronics and appliances, healthcare, chemical engineers, aerospace, paper and food, among other industries.

Lean manufacturing is based on five principles:

-

Define Value - Determine the value that your business brings to society. Also, identify what sets you apart from your competitors.

-

Reduce waste - Stop any activity that isn't adding value to the supply chains.

-

Create Flow. Ensure that your work is uninterrupted and flows seamlessly.

-

Standardize and Simplify – Make processes as consistent, repeatable, and as simple as possible.

-

Build Relationships- Develop personal relationships with both internal as well as external stakeholders.

Although lean manufacturing has always been around, it is gaining popularity in recent years because of a renewed interest for the economy after 2008's global financial crisis. Many businesses have adopted lean production techniques to make them more competitive. Many economists believe lean manufacturing will play a major role in economic recovery.

Lean manufacturing, which has many benefits, is now a standard practice in the automotive industry. These include improved customer satisfaction, reduced inventory levels, lower operating costs, increased productivity, and better overall safety.

The principles of lean manufacturing can be applied in almost any area of an organization. Lean manufacturing is most useful in the production sector of an organisation because it ensures that each step in the value-chain is efficient and productive.

There are three main types:

-

Just-in Time Manufacturing: This lean manufacturing method is commonly called "pull systems." JIT is a method in which components are assembled right at the moment of use, rather than being manufactured ahead of time. This approach reduces lead time, increases availability and reduces inventory.

-

Zero Defects Manufacturing, (ZDM): ZDM is focused on ensuring that no defective products leave the manufacturing facility. If a part is required to be repaired on the assembly line, it should not be scrapped. This is also true for finished products that require minor repairs before shipping.

-

Continuous Improvement (CI),: Continuous improvement aims improve the efficiency and effectiveness of operations by continuously identifying issues and making changes to reduce waste. Continuous improvement involves continuous improvement of processes and people as well as tools.