You can find your path to supply chain analytics training courses, whether you're looking for a new career or just want to increase your knowledge to keep up the pace with the ever-changing business landscape. It is an integral component of every company's operation. Companies are able to meet customer expectations with the help of data collection and analysis tools.

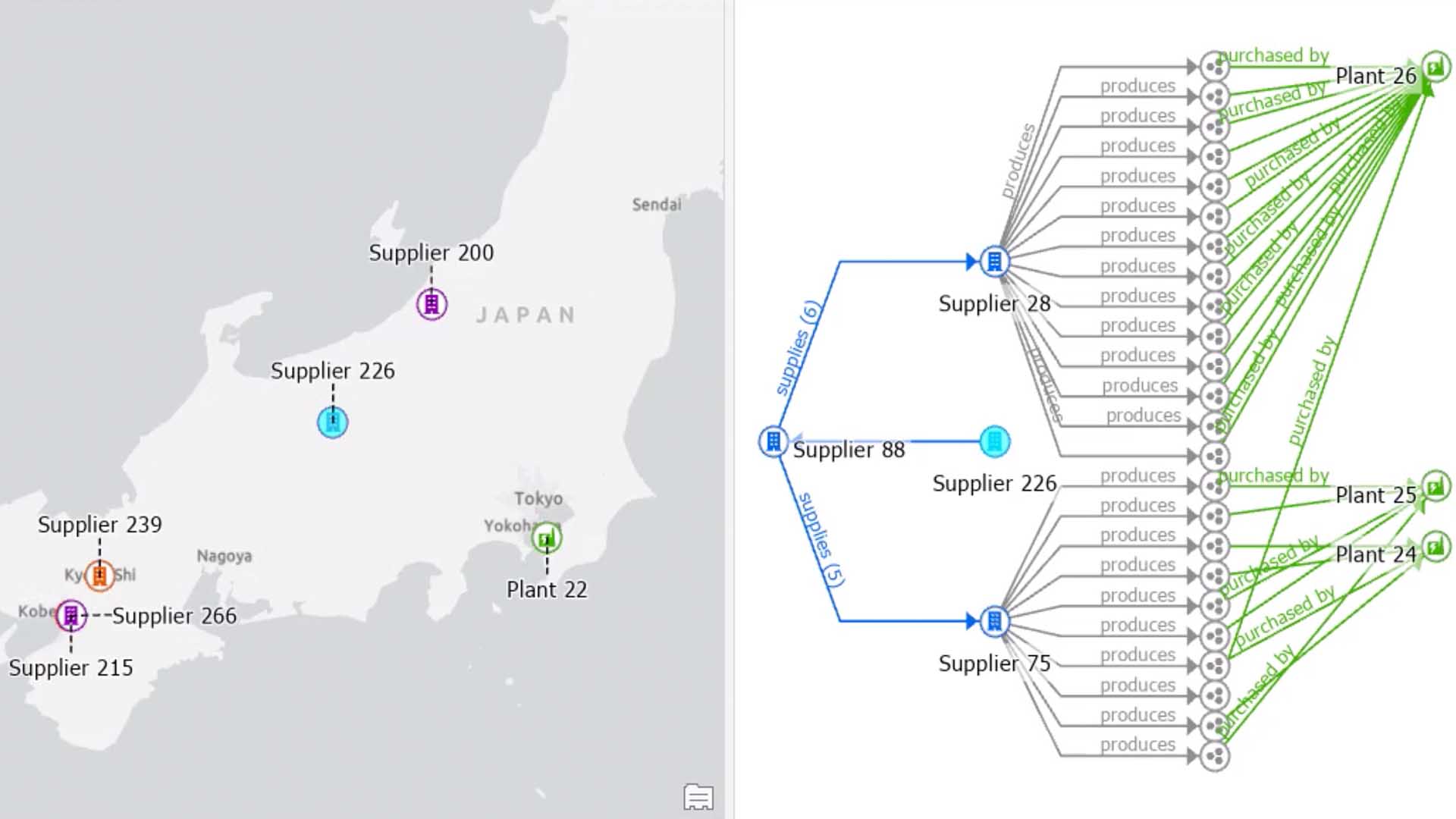

Supply chain analytics courses teach you to interpret voluminous data to make sense of it and to discover patterns that can be used to inform future decisions. It can help you to identify the most effective course of action. This will allow you to make faster and more accurate decision. It can help you increase your working capital. It can help you to identify the inventory levels required to provide the services that your customers want. It can even help you mitigate potential risks.

New products and services are continuously being added to the global market. Many companies use data to improve their supply chain efficiency. It can also be used to forecast future demand. This course teaches you how predictive analytics and data-mining can help you analyze your supply chains. These techniques are useful for developing inventory policies, forecasting future demand, and performing predictive maintenance.

The course also explains the components of supply chains and how they can be combined in order to create an integrated system. This covers the logistics planning process, import-export procedures, as well as containerisation. The course also includes information on inventory management, shipping scheduling, and air cargo administration. The course also covers data cleansing and visualization.

You will also be introduced to machine learning, which is a field that uses algorithms to find patterns in data. This is particularly useful for the supply chain industry. It is used to perform customer segmentation, and can be used with Python to develop predictive models.

Furthermore, this course covers ethics and key drivers of supply-chain management. It also explains basic concepts of inventory management and supplier selection as well as how lean six sigma can be applied. It also discusses the importance flexibility and innovation.

The supply chain analytics courses will give you an understanding of why data-driven decision making is so important in today’s business environment. It helps you to make better decisions, which can save money and increase efficiency. It also gives you the ability to analyze your data to find new ways to improve your organization. This can help you improve your company's bottom line, and it is an essential part of any supply chain management course.

Faculty have real-world experience teaching supply chain management. This course will give you an overview of key areas in supply chain management and help you choose the best technology for you. The manual also covers the many models that can be used in supply-chain management, including the inventory model. This course will teach you about the most popular tools for analyzing data and how to use them in order to improve your supply chain efficiency.

FAQ

What are the 4 types manufacturing?

Manufacturing is the process by which raw materials are transformed into useful products through machines and processes. It includes many different activities like designing, building and testing, packaging, shipping and selling, as well as servicing.

Why should you automate your warehouse?

Modern warehouses have become more dependent on automation. The rise of e-commerce has led to increased demand for faster delivery times and more efficient processes.

Warehouses should be able adapt quickly to new needs. They must invest heavily in technology to do this. Automation of warehouses offers many benefits. Here are some reasons why it's worth investing in automation:

-

Increases throughput/productivity

-

Reduces errors

-

Accuracy is improved

-

Safety is boosted

-

Eliminates bottlenecks

-

This allows companies to scale easily

-

It makes workers more efficient

-

Provides visibility into everything that happens in the warehouse

-

Enhances customer experience

-

Improves employee satisfaction

-

Minimizes downtime and increases uptime

-

Ensures quality products are delivered on time

-

Removing human error

-

Helps ensure compliance with regulations

What does it mean to be a manufacturer?

Manufacturing Industries are those businesses that make products for sale. Consumers are people who purchase these goods. This is accomplished by using a variety of processes, including production, distribution and retailing. They create goods from raw materials, using machines and various other equipment. This includes all types of manufactured goods, including food items, clothing, building supplies, furniture, toys, electronics, tools, machinery, vehicles, pharmaceuticals, medical devices, chemicals, and many others.

Statistics

- In the United States, for example, manufacturing makes up 15% of the economic output. (twi-global.com)

- Many factories witnessed a 30% increase in output due to the shift to electric motors. (en.wikipedia.org)

- According to the United Nations Industrial Development Organization (UNIDO), China is the top manufacturer worldwide by 2019 output, producing 28.7% of the total global manufacturing output, followed by the United States, Japan, Germany, and India.[52][53] (en.wikipedia.org)

- According to a Statista study, U.S. businesses spent $1.63 trillion on logistics in 2019, moving goods from origin to end user through various supply chain network segments. (netsuite.com)

- [54][55] These are the top 50 countries by the total value of manufacturing output in US dollars for its noted year according to World Bank.[56] (en.wikipedia.org)

External Links

How To

How to Use the 5S to Increase Productivity In Manufacturing

5S stands to stand for "Sort", “Set In Order", “Standardize", and "Store". Toyota Motor Corporation was the first to develop the 5S approach in 1954. It helps companies achieve higher levels of efficiency by improving their work environment.

This method has the basic goal of standardizing production processes to make them repeatable. This means that tasks such as cleaning, sorting, storing, packing, and labeling are performed daily. This knowledge allows workers to be more efficient in their work because they are aware of what to expect.

Implementing 5S involves five steps: Sort, Set in Order, Standardize Separate, Store, and Each step has a different action and leads to higher efficiency. Sorting things makes it easier to find them later. Once you have placed items in an ordered fashion, you will put them together. You then organize your inventory in groups. Make sure everything is correctly labeled when you label your containers.

This process requires employees to think critically about how they do their job. Employees must be able to see why they do what they do and find a way to achieve them without having to rely on their old methods. To implement the 5S system, employees must acquire new skills and techniques.

In addition to increasing efficiency, the 5S method also improves morale and teamwork among employees. They feel more motivated to work towards achieving greater efficiency as they see the results.