As nuclear technicians, you are responsible for maintaining and monitoring equipment and machines that are used in the production and testing of nuclear energy. A nuclear technician usually works for a nuclear power plant and can advance to higher levels of responsibility as they gain experience. They might perform radiation testing, troubleshoot devices, or collect data to assess the system's quality.

An associate's/bachelor's in nuclear technology is necessary to be a qualified nuclear technician. Further training is required. Most employers require two years of specialized training to qualify for a nuclear technician job. After completing the training, you are eligible to apply for a job as a nuclear technician at a laboratory or power plant. You can also specialize in nuclear waste management and become a nuclear engineer.

A nuclear technician usually works alongside scientists involved in nuclear energy production and research. They can also monitor and record radiation levels within nuclear reactors. A nuclear technician may also operate specialized equipment such as remote-control panels. They can also instruct staff about radiation safety procedures.

Additional to the general duties of a nuclear technician, they may be skilled in radiation protection or waste management. Some nuclear technicians might be required to have security clearance. They may also need to take advanced science and math courses.

Government agencies may also consider nuclear technicians. These jobs often involve thinking, researching facts, and analyzing complex situations. The average hourly salary for a nuclear technician may be $38,10, but this is not the case.

A nuclear technician can also be a technical specialist. They can also earn more if their responsibilities are increased. This field offers high salaries in many industries.

Based on your education and experience, the salary of nuclear technicians will vary. You can expect to earn $31,000 an year as an entry-level technician. Nuclear technicians who have worked for years can earn $115,000. This field is expected see high growth in the next 10 years. There should be around 1,400 new jobs in this field.

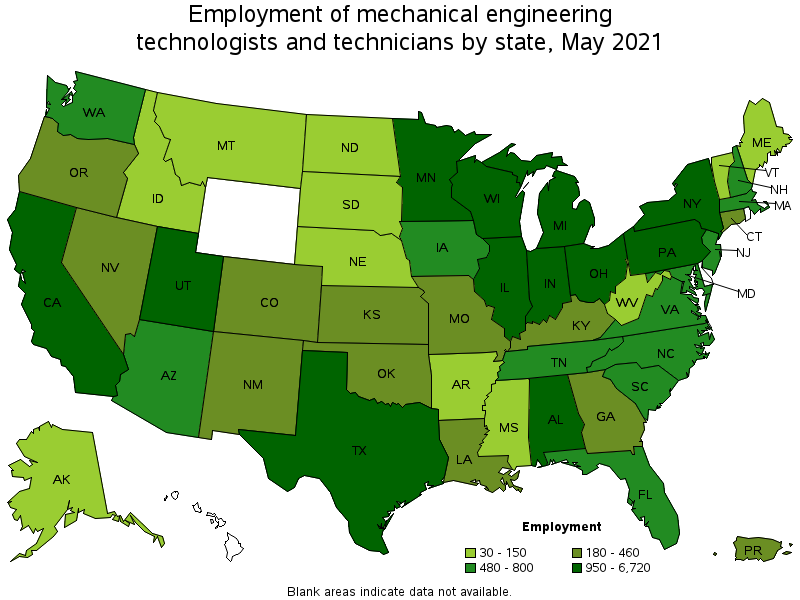

The salaries of nuclear technicians can vary from one place to the next. In Illinois, for example, the average salary is $121,020 per year. California is home to the highest salary for Nuclear Technicians. It may vary from one state to another, but the national average is $126,000. Higher salaries are possible for people with advanced degrees, or nuclear technician degrees.

Although the Nuclear Technician salary may be the highest, this doesn't necessarily mean it is the best. You'll also need to have good deductive reasoning skills, as well as a passion for science and the ability to think critically. Additionally, you will need to be able to operate specialized equipment. Many nuclear technicians go on to further education to get certifications.

FAQ

Is automation important in manufacturing?

Not only are service providers and manufacturers important, but so is automation. They can provide services more quickly and efficiently thanks to automation. It reduces human errors and improves productivity, which in turn helps them lower their costs.

What are manufacturing and logistic?

Manufacturing is the production of goods using raw materials. Logistics includes all aspects related to supply chain management, such as procurement, distribution planning, inventory control and transportation. As a broad term, manufacturing and logistics often refer to both the creation and delivery of products.

How can excess manufacturing production be reduced?

Improved inventory management is the key to reducing overproduction. This would reduce time spent on activities such as purchasing, stocking, and maintaining excess stock. This could help us free up our time for other productive tasks.

One way to do this is to adopt a Kanban system. A Kanban board is a visual display used to track work in progress. In a Kanban system, work items move through a sequence of states until they reach their final destination. Each state represents a different priority level.

If work is moving from one stage to the other, then the current task can be completed and moved on to the next. It is possible to keep a task in the beginning stages until it gets to the end.

This keeps work moving and ensures no work is lost. Managers can monitor the work being done by Kanban boards to see what is happening at any given time. This data allows them adjust their workflow based upon real-time data.

Lean manufacturing, another method to control inventory levels, is also an option. Lean manufacturing emphasizes eliminating waste in all phases of production. Anything that does not contribute to the product's value is considered waste. Some common types of waste include:

-

Overproduction

-

Inventory

-

Unnecessary packaging

-

Overstock materials

By implementing these ideas, manufacturers can improve efficiency and cut costs.

What kind of jobs are there in logistics?

Logistics can offer many different jobs. Here are some examples:

-

Warehouse workers – They load and unload pallets and trucks.

-

Transport drivers - These are people who drive trucks and trailers to transport goods or perform pick-ups.

-

Freight handlers are people who sort and pack freight into warehouses.

-

Inventory managers - These are responsible for overseeing the stock of goods in warehouses.

-

Sales representatives: They sell products to customers.

-

Logistics coordinators are responsible for organizing and planning logistics operations.

-

Purchasing agents are those who purchase goods and services for the company.

-

Customer service representatives - They answer calls and emails from customers.

-

Shippers clerks - They process shipping order and issue bills.

-

Order fillers: They fill orders based off what has been ordered and shipped.

-

Quality control inspectors are responsible for inspecting incoming and outgoing products looking for defects.

-

Others - There is a variety of other jobs in logistics. These include transportation supervisors and cargo specialists.

What do you mean by warehouse?

Warehouses and storage facilities are where goods are kept before being sold. It can be either an indoor or outdoor space. It may also be an indoor space or an outdoor area.

What does it take to run a logistics business?

You need to have a lot of knowledge and skills to manage a successful logistic business. To communicate effectively with clients and suppliers, you must be able to communicate well. You will need to know how to interpret data and draw conclusions. You need to be able work under pressure and manage stressful situations. To improve efficiency, you must be innovative and creative. You need to have strong leadership qualities to motivate team members and direct them towards achieving organizational goals.

It is important to be organized and efficient in order to meet tight deadlines.

How can I learn about manufacturing?

You can learn the most about manufacturing by getting involved in it. You can read books, or watch instructional videos if you don't have the opportunity to do so.

Statistics

- In the United States, for example, manufacturing makes up 15% of the economic output. (twi-global.com)

- You can multiply the result by 100 to get the total percent of monthly overhead. (investopedia.com)

- It's estimated that 10.8% of the U.S. GDP in 2020 was contributed to manufacturing. (investopedia.com)

- In 2021, an estimated 12.1 million Americans work in the manufacturing sector.6 (investopedia.com)

- Many factories witnessed a 30% increase in output due to the shift to electric motors. (en.wikipedia.org)

External Links

How To

Six Sigma and Manufacturing

Six Sigma is defined by "the application SPC (statistical process control) techniques to achieve continuous improvements." It was developed by Motorola's Quality Improvement Department at their plant in Tokyo, Japan, in 1986. Six Sigma is a method to improve quality through standardization and elimination of defects. In recent years, many companies have adopted this method because they believe there is no such thing as perfect products or services. Six Sigma aims to reduce variation in the production's mean value. It is possible to measure the performance of your product against an average and find the percentage of time that it differs from the norm. If there is a significant deviation from the norm, you will know that something needs to change.

Understanding how variability works in your company is the first step to Six Sigma. Once you have a good understanding of the basics, you can identify potential sources of variation. Also, you will need to identify the sources of variation. Random variations are caused by human errors. Systematic variations can be caused by outside factors. Random variations would include, for example, the failure of some widgets to fall from the assembly line. If however, you notice that each time you assemble a widget it falls apart in exactly the same spot, that is a problem.

Once you've identified the problem areas you need to find solutions. It might mean changing the way you do business or redesigning it entirely. After implementing the new changes, you should test them again to see if they worked. If they don’t work, you’ll need to go back and rework the plan.