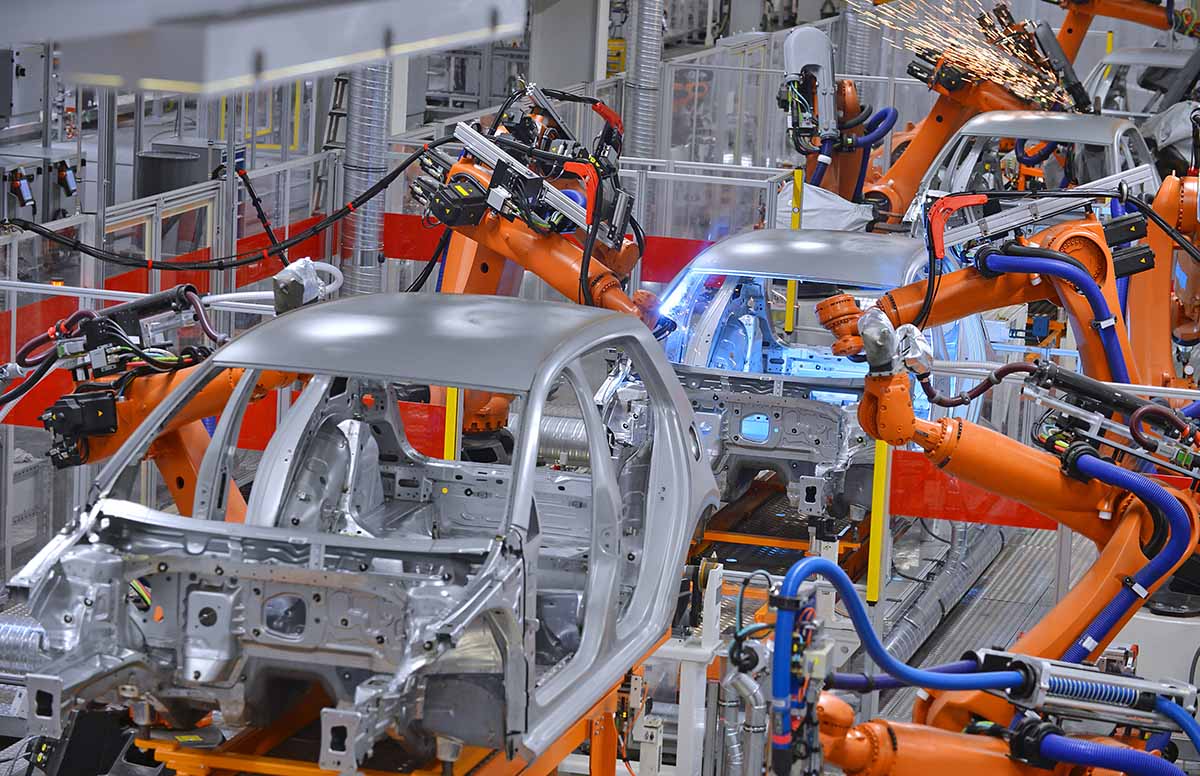

Industrial engineers design efficient systems that integrate workers, machines, materials, information and energy to make a product or provide a service. They can be found in an office environment or in production environments, such a a manufacturing facility or a warehouse.

Industrial Engineer Entry in Texas

Your job as an industrial engineer is to ensure that production processes run smoothly. Your responsibilities include analyzing problems, troubleshooting issues and implementing changes to improve efficiency. You may also train and support technicians who use the systems and equipment you designed.

Your duties will differ depending on your company and the needs of that particular organization. You may be asked by some manufacturers to design a procedure for dealing with hazardous waste. Some manufacturers require that you develop a method for controlling and monitoring the flow of raw material.

Manufacturers are always looking for ways to cut costs and increase efficiency, so you could find yourself working on projects to reduce waste in production processes. This may involve reducing the quantity of inventory in the warehouse, improving machinery efficiency or identifying and eliminating wasteful processes.

Work for a company that manufactures transportation equipment or computer and electronic products. These jobs tend to be full-time. Employment is expected grow by 10% within the next 10 years.

Manufacturing Engineering Jobs Texas

For a start, you could work in a facility that makes energy or heavy machinery. Many plant managers are looking for candidates who have this kind of experience.

During the time you spend at the plant, it is expected that you participate in various training programs and seminars. You will be able to become a better member of the team by participating in these training programs. You may also be asked to conduct specialized research, which helps you improve your skills as an Industrial Engineer.

Manufacturing Engineer at Eastman

If your skills are in the right place, you could be offered a position as an industrial engineer at Eastman Chemical in Mcallen, Texas. This fast-paced, rewarding job offers you the chance to work for a leading energy and technology company.

As an industrial engineers, you'll be responsible for the implementation and maintenance of engineered labor standard in distribution centres across the nation. You will be a key part of the industrial engineering team, responsible for presenting and providing engineering labor standards to associates at these facilities, assisting in the development of training methods and materials, facilitating change management activities as needed and conducting regular data collection and analysis.

FAQ

What does manufacturing industry mean?

Manufacturing Industries refers to businesses that manufacture products. The people who buy these products are called consumers. To accomplish this goal, these companies employ a range of processes including distribution, sales, management, and production. These companies produce goods using raw materials and other equipment. This includes all types manufactured goods such as clothing, building materials, furniture, electronics, tools and machinery.

How can manufacturing prevent production bottlenecks?

To avoid production bottlenecks, ensure that all processes run smoothly from the moment you receive your order to the time the product ships.

This includes planning for both capacity requirements and quality control measures.

Continuous improvement techniques such Six Sigma are the best method to accomplish this.

Six Sigma is a management method that helps to improve quality and reduce waste.

It's all about eliminating variation and creating consistency in work.

What is the difference between Production Planning and Scheduling?

Production Planning (PP) is the process of determining what needs to be produced at any given point in time. Forecasting and identifying production capacity are two key elements to this process.

Scheduling is the process that assigns dates to tasks so they can get completed within a given timeframe.

What is the responsibility of a manufacturing manager?

A manufacturing manager must make sure that all manufacturing processes run smoothly and effectively. They must also be alert to any potential problems and take appropriate action.

They must also be able to communicate with sales and marketing departments.

They should be informed about industry trends and be able make use of this information to improve their productivity and efficiency.

How can manufacturing efficiency be improved?

First, determine which factors have the greatest impact on production time. We then need to figure out how to improve these variables. If you don’t know where to begin, consider which factors have the largest impact on production times. Once you have identified them, it is time to identify solutions.

How can I find out more about manufacturing?

Hands-on experience is the best way to learn more about manufacturing. You can also read educational videos or take classes if this isn't possible.

How can we reduce manufacturing overproduction?

The key to reducing overproduction lies in developing better ways to manage inventory. This would reduce time spent on activities such as purchasing, stocking, and maintaining excess stock. We could use these resources to do other productive tasks.

You can do this by adopting a Kanban method. A Kanban board is a visual display used to track work in progress. Kanban systems are where work items travel through a series of states until reaching their final destination. Each state is assigned a different priority.

When work is completed, it can be transferred to the next stage. It is possible to keep a task in the beginning stages until it gets to the end.

This allows for work to continue moving forward, while also ensuring that there is no work left behind. A Kanban board allows managers to monitor how much work is being completed at any given moment. This data allows them adjust their workflow based upon real-time data.

Another way to control inventory levels is to implement lean manufacturing. Lean manufacturing focuses on eliminating waste throughout the entire production chain. Anything that doesn't add value to the product is considered waste. These are some of the most common types.

-

Overproduction

-

Inventory

-

Packaging not required

-

Exceed materials

Manufacturers can increase efficiency and decrease costs by implementing these ideas.

Statistics

- [54][55] These are the top 50 countries by the total value of manufacturing output in US dollars for its noted year according to World Bank.[56] (en.wikipedia.org)

- (2:04) MTO is a production technique wherein products are customized according to customer specifications, and production only starts after an order is received. (oracle.com)

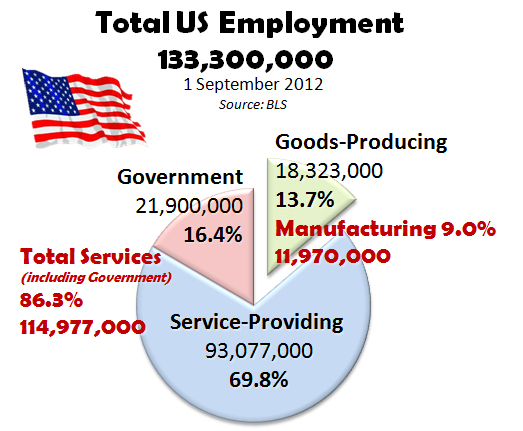

- According to the United Nations Industrial Development Organization (UNIDO), China is the top manufacturer worldwide by 2019 output, producing 28.7% of the total global manufacturing output, followed by the United States, Japan, Germany, and India.[52][53] (en.wikipedia.org)

- In the United States, for example, manufacturing makes up 15% of the economic output. (twi-global.com)

- Many factories witnessed a 30% increase in output due to the shift to electric motors. (en.wikipedia.org)

External Links

How To

How to use the Just-In Time Method in Production

Just-intime (JIT), a method used to lower costs and improve efficiency in business processes, is called just-in-time. It is a process where you get the right amount of resources at the right moment when they are needed. This means that you only pay for what you actually use. Frederick Taylor developed the concept while working as foreman in early 1900s. He observed how workers were paid overtime if there were delays in their work. He decided to ensure workers have enough time to do their jobs before starting work to improve productivity.

JIT is an acronym that means you need to plan ahead so you don’t waste your money. You should also look at the entire project from start to finish and make sure that you have sufficient resources available to deal with any problems that arise during the course of your project. You can anticipate problems and have enough equipment and people available to fix them. This way, you won't end up paying extra money for things that weren't really necessary.

There are several types of JIT techniques:

-

Demand-driven: This JIT is where you place regular orders for the parts/materials that are needed for your project. This will allow for you to track the material that you have left after using it. This will allow you to calculate how long it will take to make more.

-

Inventory-based: You stock materials in advance to make your projects easier. This allows for you to anticipate how much you can sell.

-

Project-driven: This is an approach where you set aside enough funds to cover the cost of your project. Once you have an idea of how much material you will need, you can purchase the necessary materials.

-

Resource-based JIT : This is probably the most popular type of JIT. You allocate resources based on the demand. For instance, if you have a lot of orders coming in, you'll assign more people to handle them. If there aren't many orders, you will assign fewer people.

-

Cost-based: This is the same as resource-based except that you don't care how many people there are but how much each one of them costs.

-

Price-based: This is a variant of cost-based. However, instead of focusing on the individual workers' costs, this looks at the total price of the company.

-

Material-based is an alternative to cost-based. Instead of looking at the total cost in the company, this method focuses on the average amount of raw materials that you consume.

-

Time-based JIT is another form of resource-based JIT. Instead of worrying about how much each worker costs, you can focus on how long the project takes.

-

Quality-based: This is yet another variation of resource-based JIT. Instead of looking at the labor costs and time it takes to make a product, think about its quality.

-

Value-based: This is one of the newest forms of JIT. This is where you don't care about how the products perform or whether they meet customers' expectations. Instead, your focus is on the value you bring to the market.

-

Stock-based: This stock-based method focuses on the actual quantity of products being made at any given time. It's useful when you want maximum production and minimal inventory.

-

Just-in-time (JIT) planning: This is a combination of JIT and supply chain management. It is the process of scheduling components' delivery as soon as they have been ordered. This is important as it reduces lead time and increases throughput.