China is second in terms of global economy, and it's a major force in manufacturing. It has experienced significant economic growth in recent years and is now a major manufacturer of many different products. The industrial sector accounts for 33% of the GDP, and is the largest industry in the nation.

China's industry is among the fastest growing in the entire world. Its output has increased largely as a result of its transition from state-owned enterprise (SOE) reforms to open-market policies. China's industrial sector has grown rapidly since 1978 when the government implemented these reforms.

China has provided free land, cheap financing, low-interest loan and other benefits for producers to help them develop their industries. It allows them to compete in the marketplace and sell at lower rates than their rivals abroad.

In the early years of China's development, these subsidies were key to its growth. But in recent decades, the government's assistance has diminished and China is now dominated almost entirely by private enterprises.

It means that the government's role in China's economic growth is now less important. The government is no longer the main driving force of China's economy.

China's productivity has also grown rapidly over the last few decades. This has led a lot of jobs to be created, especially in services.

China's manufacturing industry is the largest in the world, accounting for almost 46.8%. This is due in large part to the amount of money that Chinese have invested into their heavy industries.

China's Economy is comprised of many industries. Each plays a vital role in its operation. Agriculture, energy and manufacturing are all important industries.

China's industrial sector has steadily grown over the last 100 years. It has become the world's largest producer of cement, steel, and chemical fertilizers.

It is also the leading exporter of cotton and textiles. China's cotton industry, which accounts for 10% of global production, is a vital part of China's economy.

Construction, mining, oil and gas are also important industries in China. These industries all contribute to the economy of China and employ large numbers of people.

The manufacturing industry plays a key role in China's overall economy. It is important to find a good manufacturer that can help you and your business to grow. This can be difficult, but if you know what to look for, it will be much easier.

FAQ

What are the four types of manufacturing?

Manufacturing refers the process of turning raw materials into useful products with machines and processes. Manufacturing involves many activities, including designing, building, testing and packaging, shipping, selling, service, and so on.

How can manufacturing excess production be decreased?

It is essential to find better ways to manage inventory to reduce overproduction. This would decrease the time that is spent on inefficient activities like purchasing, storing, or maintaining excess stock. We could use these resources to do other productive tasks.

One way to do this is to adopt a Kanban system. A Kanbanboard is a visual tool that allows you to keep track of the work being done. Work items are moved through various states to reach their destination in a Kanban system. Each state represents a different priority.

To illustrate, work can move from one stage or another when it is complete enough for it to be moved to a new stage. But if a task remains in the beginning stages it will stay that way until it reaches its end.

This keeps work moving and ensures no work is lost. A Kanban board allows managers to monitor how much work is being completed at any given moment. This allows them to adjust their workflows based on real-time information.

Another way to control inventory levels is to implement lean manufacturing. Lean manufacturing seeks to eliminate waste from every step of the production cycle. Waste includes anything that does not add value to the product. Here are some examples of common types.

-

Overproduction

-

Inventory

-

Unnecessary packaging

-

Materials in excess

By implementing these ideas, manufacturers can improve efficiency and cut costs.

What skills are required to be a production manager?

Production planners must be flexible, organized, and able handle multiple tasks. It is also important to be able communicate with colleagues and clients.

What is meant by manufacturing industries?

Manufacturing Industries is a group of businesses that produce goods for sale. Consumers are the people who purchase these products. These companies use various processes such as production, distribution, retailing, management, etc., to fulfill this purpose. They make goods from raw materials with machines and other equipment. This includes all types of manufactured goods, including food items, clothing, building supplies, furniture, toys, electronics, tools, machinery, vehicles, pharmaceuticals, medical devices, chemicals, and many others.

How can I find out more about manufacturing?

You can learn the most about manufacturing by getting involved in it. But if that is not possible you can always read books and watch educational videos.

Statistics

- Many factories witnessed a 30% increase in output due to the shift to electric motors. (en.wikipedia.org)

- Job #1 is delivering the ordered product according to specifications: color, size, brand, and quantity. (netsuite.com)

- [54][55] These are the top 50 countries by the total value of manufacturing output in US dollars for its noted year according to World Bank.[56] (en.wikipedia.org)

- According to a Statista study, U.S. businesses spent $1.63 trillion on logistics in 2019, moving goods from origin to end user through various supply chain network segments. (netsuite.com)

- In the United States, for example, manufacturing makes up 15% of the economic output. (twi-global.com)

External Links

How To

How to Use Lean Manufacturing for the Production of Goods

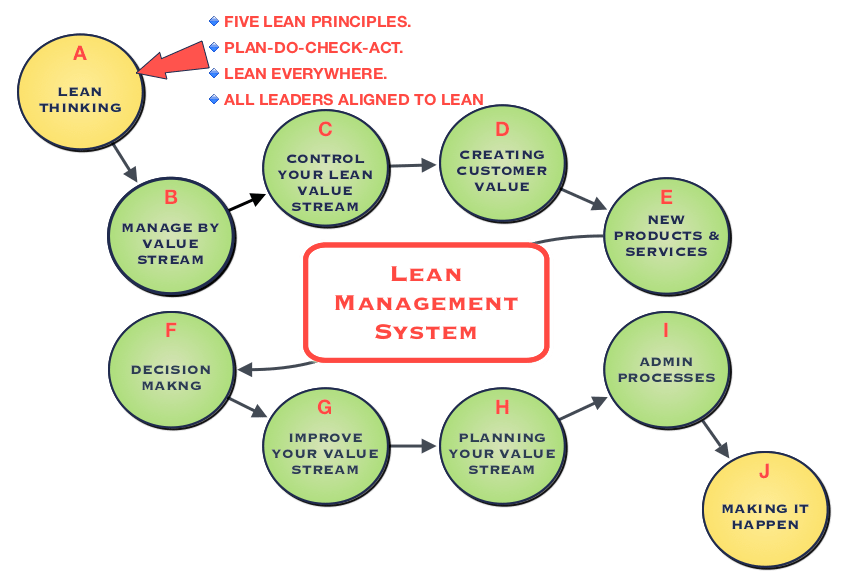

Lean manufacturing is an approach to management that aims for efficiency and waste reduction. It was developed in Japan between 1970 and 1980 by Taiichi Ohno. TPS founder Kanji Tyoda gave him the Toyota Production System, or TPS award. Michael L. Watkins published the book "The Machine That Changed the World", which was the first to be published about lean manufacturing.

Lean manufacturing can be described as a set or principles that are used to improve quality, speed and cost of products or services. It emphasizes the elimination and minimization of waste in the value stream. The five-steps of Lean Manufacturing are just-in time (JIT), zero defect and total productive maintenance (TPM), as well as 5S. Lean manufacturing focuses on eliminating non-value-added activities such as rework, inspection, and waiting.

Lean manufacturing not only improves product quality but also reduces costs. Companies can also achieve their goals faster by reducing employee turnover. Lean manufacturing is considered one of the most effective ways to manage the entire value chain, including suppliers, customers, distributors, retailers, and employees. Lean manufacturing practices are widespread in many industries. Toyota's philosophy, for example, is what has enabled it to be successful in electronics, automobiles, medical devices, healthcare and chemical engineering as well as paper and food.

Five basic principles of Lean Manufacturing are included in lean manufacturing

-

Define Value: Identify the social value of your business and what sets you apart.

-

Reduce Waste - Remove any activity which doesn't add value to your supply chain.

-

Create Flow - Ensure work moves smoothly through the process without interruption.

-

Standardize and simplify – Make processes as repeatable and consistent as possible.

-

Building Relationships – Establish personal relationships with both external and internal stakeholders.

Lean manufacturing is not a new concept, but it has been gaining popularity over the last few years due to a renewed interest in the economy following the global financial crisis of 2008. To increase their competitiveness, many businesses have turned to lean manufacturing. Many economists believe lean manufacturing will play a major role in economic recovery.

Lean manufacturing is becoming a popular practice in automotive. It has many advantages. These include better customer satisfaction and lower inventory levels. They also result in lower operating costs.

Lean manufacturing can be applied to almost every aspect of an organization. It is especially useful for the production aspect of an organization, as it ensures that every step in the value chain is efficient and effective.

There are three types of lean manufacturing.

-

Just-in Time Manufacturing: This lean manufacturing method is commonly called "pull systems." JIT stands for a system where components are assembled on the spot rather than being made in advance. This approach aims to reduce lead times, increase the availability of parts, and reduce inventory.

-

Zero Defects Manufacturing - ZDM: ZDM focuses its efforts on making sure that no defective units leave a manufacturing facility. If a part is required to be repaired on the assembly line, it should not be scrapped. This applies to finished products, which may need minor repairs before they are shipped.

-

Continuous Improvement: Continuous Improvement aims to improve efficiency by continually identifying problems and making adjustments to eliminate or minimize waste. Continuous Improvement involves continuous improvement of processes.