Located just a short drive from Topeka and Salina, Wichita is home to a lot of great things to do and see. It is also an ideal place to do business, if you are looking for new locations for your company. CTDI may be the right place for you if you're looking for logistics services.

CTDI can offer you logistics services. While there are many companies available, it stands out. CTDI provides full-service engineering services and logistical support to cable companies. CTDI not only offers the best solutions for the communication industry but also improves the efficiency of their logistic operations. Customers can rest assured that their goods will arrive on time and in good condition.

CTDI's Wichita, Kansas facility is located at 3434 North Comotara Street. CTDI also operates 47 locations in Canada and China. Although the company employs a few people, the company is growing as it begins to serve the markets in Wichita and Oklahoma City.

CTDI has been operating for many years and offers services to some the biggest cable providers in the United States. CTDI has a Cisco certified repair facility. They also have many facilities in Canada, China, Europe and elsewhere. In addition, they have a number of telecommunications products in their inventory, including wireless and wireline telephones and cable television sets. Their products are used by many cable companies, including Spectrum, AT&T, Time Warner, Verizon, Comcast, and Spectrum.

CTDI's most remarkable achievement is the acquisition of a stateofthe art distribution center for Cox Communications. This Cox Distribution Center is located at Wichita, Kansas. It will be one of the three largest in Kansas. The company plans expand the facility in order to offer a repair and maintenance service. CTDI's Wichita workforce will grow as the center expands.

The company also owns a telecommunications facility in West Chester (PA). This facility has received a number of awards, including being the cheapest carrier in its class by the Transportation Research Board and being the cheapest carrier in its class by state by the Society for Logistics Management. Other impressive achievements include providing engineering services for the cable industry. The company's most impressive feat was its ability to provide services to the largest telecommunications companies in the world.

CTDI's other most impressive accomplishment is its use of the latest and greatest technology to provide the best logistics solutions for its customers. The company also offers equal opportunities for all employees, regardless of gender or race. You can also enjoy a variety of fun and interesting benefits like a health club, and a gym for free.

FAQ

What are the requirements to start a logistics business?

You need to have a lot of knowledge and skills to manage a successful logistic business. You must have good communication skills to interact effectively with your clients and suppliers. It is important to be able to analyse data and draw conclusions. You need to be able work under pressure and manage stressful situations. To improve efficiency, you must be innovative and creative. You will need strong leadership skills to motivate and direct your team members towards achieving their organizational goals.

You must be organized to meet tight deadlines.

Why is logistics important in manufacturing

Logistics are an essential component of any business. Logistics can help you achieve amazing results by helping to manage product flow from raw materials to finished products.

Logistics play a key role in reducing expenses and increasing efficiency.

What does warehouse refer to?

A warehouse or storage facility is where goods are stored before they are sold. It can be indoors or out. It may also be an indoor space or an outdoor area.

What types of jobs can you find in logistics

There are many types of jobs in logistics. Here are some examples:

-

Warehouse workers – They load and unload pallets and trucks.

-

Transportation drivers - They drive trucks and trailers to deliver goods and carry out pick-ups.

-

Freight handlers, - They sort out and pack freight in warehouses.

-

Inventory managers – They manage the inventory in warehouses.

-

Sales representatives - They sell products to customers.

-

Logistics coordinators – They plan and coordinate logistics operations.

-

Purchasing agents are those who purchase goods and services for the company.

-

Customer service representatives – They answer emails and phone calls from customers.

-

Ship clerks - They issue bills and process shipping orders.

-

Order fillers – They fill orders based upon what was ordered and shipped.

-

Quality control inspectors are responsible for inspecting incoming and outgoing products looking for defects.

-

Others - There is a variety of other jobs in logistics. These include transportation supervisors and cargo specialists.

Do we need to know about Manufacturing Processes before learning about Logistics?

No. It doesn't matter if you don't know anything about manufacturing before you learn about logistics. Understanding the manufacturing process will allow you to better understand logistics.

What are the responsibilities of a production planner

Production planners ensure that all project aspects are completed on time, within budget and within the scope. They also ensure that the product/service meets the client’s needs.

Statistics

- In 2021, an estimated 12.1 million Americans work in the manufacturing sector.6 (investopedia.com)

- You can multiply the result by 100 to get the total percent of monthly overhead. (investopedia.com)

- [54][55] These are the top 50 countries by the total value of manufacturing output in US dollars for its noted year according to World Bank.[56] (en.wikipedia.org)

- It's estimated that 10.8% of the U.S. GDP in 2020 was contributed to manufacturing. (investopedia.com)

- According to the United Nations Industrial Development Organization (UNIDO), China is the top manufacturer worldwide by 2019 output, producing 28.7% of the total global manufacturing output, followed by the United States, Japan, Germany, and India.[52][53] (en.wikipedia.org)

External Links

How To

How to Use Lean Manufacturing in the Production of Goods

Lean manufacturing refers to a method of managing that seeks to improve efficiency and decrease waste. It was developed by Taiichi Okono in Japan, during the 1970s & 1980s. TPS founder Kanji Takoda awarded him the Toyota Production System Award (TPS). Michael L. Watkins published the "The Machine That Changed the World", the first book about lean manufacturing. It was published in 1990.

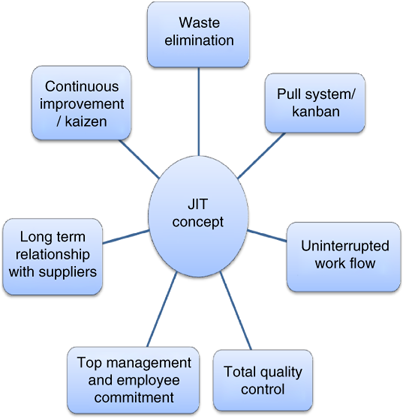

Lean manufacturing refers to a set of principles that improve the quality, speed and costs of products and services. It emphasizes eliminating waste and defects throughout the value stream. Lean manufacturing can be described as just-in–time (JIT), total productive maintenance, zero defect (TPM), or even 5S. Lean manufacturing seeks to eliminate non-value added activities, such as inspection, work, waiting, and rework.

In addition to improving product quality and reducing costs, lean manufacturing helps companies achieve their goals faster and reduces employee turnover. Lean manufacturing is a great way to manage the entire value chain including customers, suppliers, distributors and retailers as well as employees. Lean manufacturing can be found in many industries. Toyota's philosophy is a great example of this. It has helped to create success in automobiles as well electronics, appliances and healthcare.

Lean manufacturing is based on five principles:

-

Define value - Find out what your business contributes to society, and what makes it different from other competitors.

-

Reduce Waste - Eliminate any activity that doesn't add value along the supply chain.

-

Create Flow: Ensure that the work process flows without interruptions.

-

Standardize & Simplify - Make processes as consistent and repeatable as possible.

-

Build relationships - Develop and maintain personal relationships with both your internal and external stakeholders.

Lean manufacturing is not a new concept, but it has been gaining popularity over the last few years due to a renewed interest in the economy following the global financial crisis of 2008. Many businesses have adopted lean manufacturing techniques to help them become more competitive. Many economists believe lean manufacturing will play a major role in economic recovery.

Lean manufacturing has many benefits in the automotive sector. These benefits include increased customer satisfaction, reduced inventory levels and lower operating costs.

Lean manufacturing can be applied to almost every aspect of an organization. However, it is particularly useful when applied to the production side of an organization because it ensures that all steps in the value chain are efficient and effective.

There are three main types of lean manufacturing:

-

Just-in-Time Manufacturing: Also known as "pull systems", this type of lean manufacturing uses just-in-time manufacturing (JIT). JIT refers to a system in which components are assembled at the point of use instead of being produced ahead of time. This strategy aims to decrease lead times, increase availability of parts and reduce inventory.

-

Zero Defects Manufacturing (ZDM),: ZDM is a system that ensures no defective units are left the manufacturing facility. Repairing a part that is damaged during assembly should be done, not scrapping. This also applies to finished products that need minor repairs before being shipped.

-

Continuous Improvement (CI), also known as Continuous Improvement, aims at improving the efficiency of operations through continuous identification and improvement to minimize or eliminate waste. Continuous improvement refers to continuous improvement of processes as well people and tools.