There are several reasons to become an engineer, including the satisfaction of a job that solves real-world problems and the prospect of helping people. In addition, engineering is a growing field that offers good career growth and high-paying jobs.

The average engineering technologist's salary is 52,171 dollars per year. This is about 1% higher than national average $51,860. That's equal to $2,174 for each hour of work. The pay is based on an estimated federal tax rate of 22%.

Mechanical engineering technologists work with engineers who design, test, and develop machinery, appliances, and equipment. They often assist with manufacturing processes in factories or during development phases in research and development labs before production takes place. They might analyze product design and create layouts of the parts to be produced. They also may inspect test equipment for quality and calibrate new devices before they are put into use.

Other engineering technology technicians work with CAD software to convert designs produced by engineers and architects into technical drawings. Other responsibilities include entering job specs into the CAD software, making adjustments to drawings already created and completing report.

A bachelor's or a master's degree is usually required to become an engineering technician. However, if you have a degree in electrical engineering or electronics engineering, it can improve your chances of landing a job. Employers prefer to hire people with these degrees since they have more knowledge and experience about engineering technology.

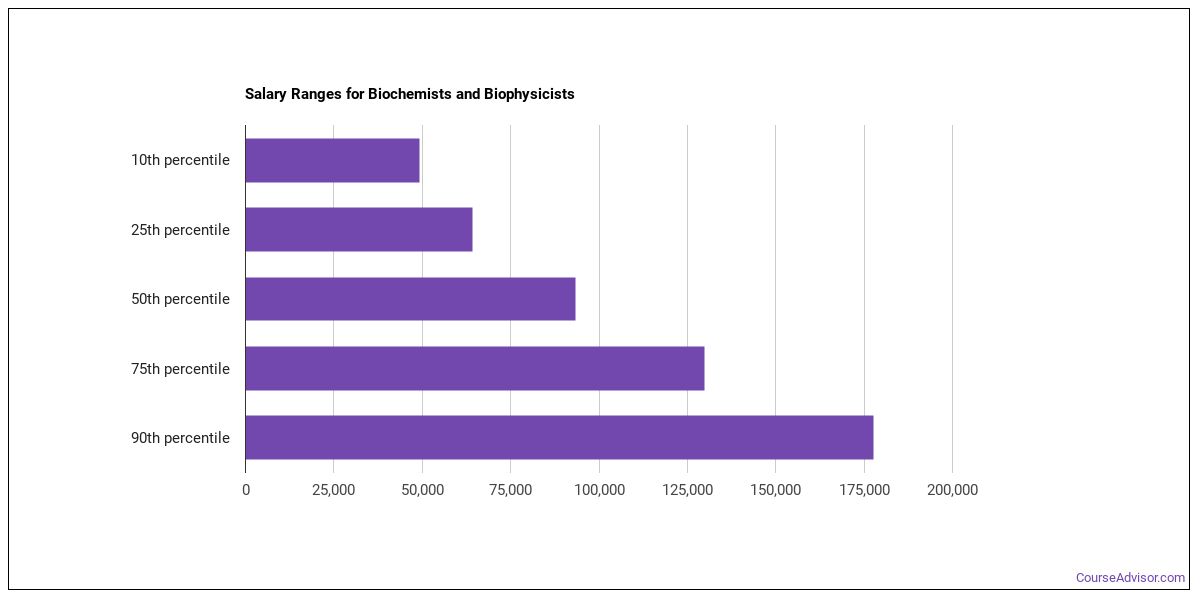

Manufacturing engineering technologists' salaries range between $32,295 and $94,100. With a median wage of $61,260, the salary range is wide. The majority of these workers are aged between 26 and 30 years. About a third fall in the age bracket of 31 to 36.

They are employed primarily in the manufacturing industry, helping engineers to solve problems that may affect the production process or the layout of the plant. They can be found at manufacturers of consumer goods, food products, industrial machines and more.

They are generally employed full time, and they are expected to work over 40 hours a weekly. They have a variety of duties, depending on the company for which they work.

Chemical engineering technologists work under the supervision of a chemical engineer to carry out experiments, develop chemical processes and perform inventory. It is possible that they are also tasked with estimating costs of manufacturing.

The group has a younger workforce, and the employment rate is lower than that of the total labor force. However, jobs are expected to increase slightly until 2031. This occupation was reported to have a salary median of $60,220 by the BLS in May 2021.

Jobs in electronics engineering technology are an excellent way to get hands-on training with electronic technology and components. These positions are a popular choice among recent graduates and can be found in manufacturing settings, research laboratories, or engineering services.

The average engineering technician salary is competitive in this field. You should consider salary potential before accepting an offer. You can raise your salary by changing jobs, earning more education or managing your experience.

FAQ

Are there ways to automate parts of manufacturing?

Yes! Yes! Automation has existed since ancient times. The wheel was invented by the Egyptians thousands of years ago. Today, robots assist in the assembly of lines.

Actually, robotics can be used in manufacturing for many purposes. These include:

-

Automation line robots

-

Robot welding

-

Robot painting

-

Robotics inspection

-

Robots that produce products

Automation can be applied to manufacturing in many other ways. 3D printing makes it possible to produce custom products in a matter of days or weeks.

What are manufacturing and logistics?

Manufacturing is the process of creating goods from raw materials by using machines and processes. Logistics includes all aspects related to supply chain management, such as procurement, distribution planning, inventory control and transportation. Logistics and manufacturing are often referred to as one thing. It encompasses both the creation of products and their delivery to customers.

How can manufacturing efficiency be improved?

First, identify the factors that affect production time. Then we need to find ways to improve these factors. If you don’t know how to start, look at which factors have the greatest impact upon production time. Once you've identified them all, find solutions to each one.

Statistics

- According to the United Nations Industrial Development Organization (UNIDO), China is the top manufacturer worldwide by 2019 output, producing 28.7% of the total global manufacturing output, followed by the United States, Japan, Germany, and India.[52][53] (en.wikipedia.org)

- Many factories witnessed a 30% increase in output due to the shift to electric motors. (en.wikipedia.org)

- In 2021, an estimated 12.1 million Americans work in the manufacturing sector.6 (investopedia.com)

- (2:04) MTO is a production technique wherein products are customized according to customer specifications, and production only starts after an order is received. (oracle.com)

- According to a Statista study, U.S. businesses spent $1.63 trillion on logistics in 2019, moving goods from origin to end user through various supply chain network segments. (netsuite.com)

External Links

How To

How to use the Just In-Time Production Method

Just-intime (JIT), a method used to lower costs and improve efficiency in business processes, is called just-in-time. It is a process where you get the right amount of resources at the right moment when they are needed. This means that your only pay for the resources you actually use. The term was first coined by Frederick Taylor, who developed his theory while working as a foreman in the early 1900s. Taylor observed that overtime was paid to workers if they were late in working. He then concluded that if he could ensure that workers had enough time to do their job before starting to work, this would improve productivity.

JIT is an acronym that means you need to plan ahead so you don’t waste your money. Look at your entire project, from start to end. Make sure you have enough resources in place to deal with any unexpected problems. You'll be prepared to handle any potential problems if you know in advance. You won't have to pay more for unnecessary items.

There are different types of JIT methods:

-

Demand-driven: This type of JIT allows you to order the parts/materials required for your project on a regular basis. This will allow for you to track the material that you have left after using it. This will let you know how long it will be to produce more.

-

Inventory-based: This allows you to store the materials necessary for your projects in advance. This allows you to predict how much you can expect to sell.

-

Project-driven: This means that you have enough money to pay for your project. You will be able to purchase the right amount of materials if you know what you need.

-

Resource-based JIT : This is probably the most popular type of JIT. Here, you allocate certain resources based on demand. For example, if there is a lot of work coming in, you will have more people assigned to them. You'll have fewer orders if you have fewer.

-

Cost-based: This is similar to resource-based, except that here you're not just concerned about how many people you have but how much each person costs.

-

Price-based: This is a variant of cost-based. However, instead of focusing on the individual workers' costs, this looks at the total price of the company.

-

Material-based: This approach is similar to cost-based. However, instead of looking at the total cost for the company, you look at how much you spend on average on raw materials.

-

Time-based JIT: This is another variant of resource-based JIT. Instead of worrying about how much each worker costs, you can focus on how long the project takes.

-

Quality-based JIT is another variant of resource-based JIT. Instead of looking at the labor costs and time it takes to make a product, think about its quality.

-

Value-based JIT: This is the latest form of JIT. In this case, you're not concerned with how well the products perform or whether they meet customer expectations. Instead, you're focused on how much value you add to the market.

-

Stock-based: This inventory-based approach focuses on how many items are being produced at any one time. It's useful when you want maximum production and minimal inventory.

-

Just-in-time (JIT) planning: This is a combination of JIT and supply chain management. It's the process of scheduling delivery of components immediately after they are ordered. It's important because it reduces lead times and increases throughput.