Industrial engineers create efficient systems to integrate workers, machines and materials with information, energy, and information in order to produce a product or service. They can work in an office, or in production settings such as a warehouse or manufacturing facility.

Industrial Engineer Entry-Level in Texas

As an industrial engineer you are responsible for the smooth running of production processes. As an industrial engineer, you will be responsible for analysing problems, troubleshooting concerns and implementing new changes to improve efficiency. You may also train and support technicians who use the systems and equipment you designed.

Your duties will differ depending on your company and the needs of that particular organization. You might be required by certain manufacturers to develop a way of handling hazardous waste. Other companies require that you create a monitoring system and control the flow.

You may find yourself working with manufacturers to reduce waste during production. It may be necessary to reduce the amount of stock in a warehouse or improve the efficiency on machinery.

Work with a company producing transportation equipment or computers and electronics. These are typically full-time positions, with employment expected to grow 10% over the next ten years.

Manufacturing Engineering Jobs Texas

Start your career in industrial engineering by taking a job at a company that makes heavy machinery, or energy equipment. It's a great opportunity to learn more about industrial engineering. Plant managers often look for candidates who already have experience.

During the time you spend at the plant, it is expected that you participate in various training programs and seminars. These training opportunities will help you become a more productive member of the team, and you might be assigned to perform specialized research that helps you refine your skills as an industrial engineer.

Eastman Company Manufacturing Engineer

If you have the right skills, Eastman Chemical could offer you a position as a industrial engineer in Mcallen. This is an exciting and fast-paced position at a leading technology, energy and engineering company.

As an Industrial Engineer, you are responsible for implementing the engineered standards of labor in all distribution centers. As a member of an industrial engineering team, you will be responsible for providing engineering labor standard to associates in these facilities.

FAQ

How can manufacturing prevent production bottlenecks?

To avoid production bottlenecks, ensure that all processes run smoothly from the moment you receive your order to the time the product ships.

This includes both quality control and capacity planning.

Continuous improvement techniques such Six Sigma are the best method to accomplish this.

Six Sigma is a management system used to improve quality and reduce waste in every aspect of your organization.

It is focused on creating consistency and eliminating variation in your work.

What are manufacturing and logistic?

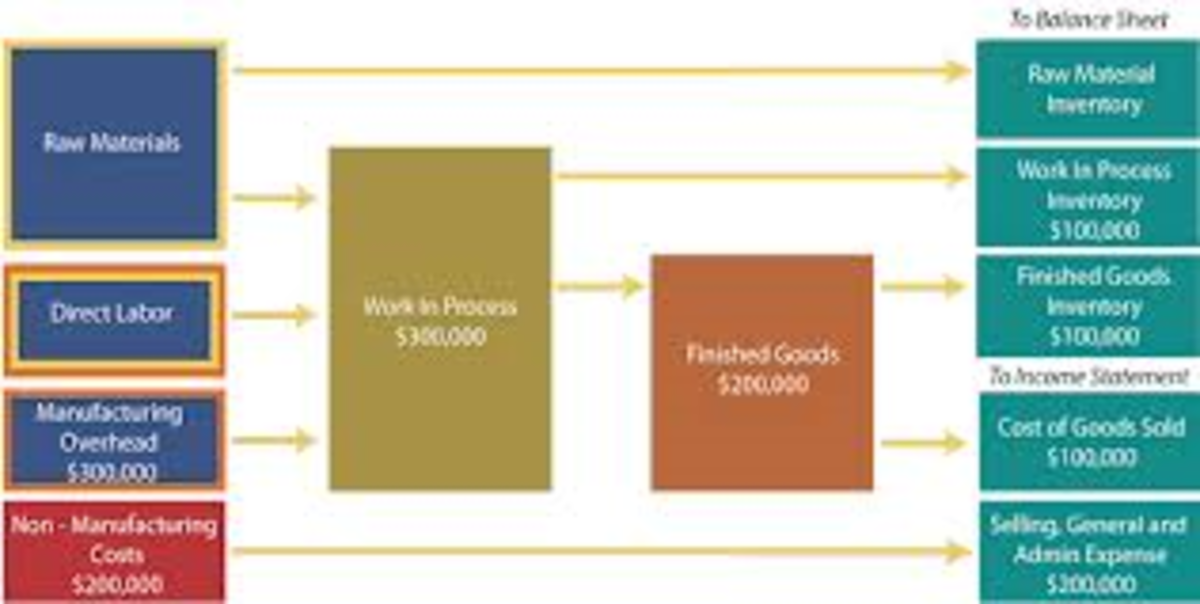

Manufacturing is the process of creating goods from raw materials by using machines and processes. Logistics is the management of all aspects of supply chain activities, including procurement, production planning, distribution, warehousing, inventory control, transportation, and customer service. Logistics and manufacturing are often referred to as one thing. It encompasses both the creation of products and their delivery to customers.

What is the importance of logistics in manufacturing?

Logistics are an integral part any business. They can help you achieve great success by helping you manage product flow from raw material to finished goods.

Logistics play a key role in reducing expenses and increasing efficiency.

What is production planning?

Production Planning includes planning for all aspects related to production. It is important to have everything ready and planned before you start shooting. It should also contain information on achieving the best results on set. It should include information about shooting locations, casting lists, crew details, equipment requirements, and shooting schedules.

It is important to first outline the type of film you would like to make. You may have decided where to shoot or even specific locations you want to use. Once you've identified the locations and scenes you want to use, you can begin to plan what elements you need for each scene. Perhaps you have decided that you need to buy a car but aren't sure which model. You could look online for cars to see what options are available, and then narrow down your choices by selecting between different makes or models.

After you've found the perfect car, it's time to start thinking about adding extras. Are you looking for people to sit in the front seats? Or maybe you just need someone to push the car around. Perhaps you would like to change the interior colour from black to white. These questions can help you decide the right look for your car. The type of shots that you are looking for is another thing to consider. You will be filming close-ups and wide angles. Maybe you want to show your engine or the steering wheel. These details will help identify the exact car you wish to film.

Once you have established all the details, you can create a schedule. A schedule will tell you when you need to start shooting and when you need to finish. The schedule will show you when to get there, what time to leave, and when to return home. It will help everyone know exactly what they have to do and when. It is possible to make arrangements in advance for additional staff if you are looking to hire. You don't want to hire someone who won't show up because he didn't know.

You will need to factor in the days that you have to film when creating your schedule. Some projects can be completed in a matter of days or weeks. Others may take several days. When you are creating your schedule, you should always keep in mind whether you need more than one shot per day or not. Multiple takes of the same location will lead to higher costs and take more time. If you are unsure if you need multiple takes, it is better to err on the side of caution and shoot fewer takes rather than risk wasting money.

Budgeting is another crucial aspect of production plan. You will be able to manage your resources if you have a realistic budget. It is possible to reduce the budget at any time if you experience unexpected problems. It is important to not overestimate how much you will spend. If you underestimate how much something costs, you'll have less money to pay for other items.

Production planning is a complicated process. But once you understand how everything works together, it becomes much easier to plan future project.

How can we reduce manufacturing overproduction?

In order to reduce excess production, you need to develop better inventory management methods. This would reduce the amount of time spent on unnecessary activities such as purchasing, storing, and maintaining excess stock. This would allow us to use our resources for more productive tasks.

This can be done by using a Kanban system. A Kanban board is a visual display used to track work in progress. Work items are moved through various states to reach their destination in a Kanban system. Each state has a different priority level.

If work is moving from one stage to the other, then the current task can be completed and moved on to the next. A task that is still in the initial stages of a process will be considered complete until it moves on to the next stage.

This allows work to move forward and ensures that no work is missed. Managers can monitor the work being done by Kanban boards to see what is happening at any given time. This information allows managers to adjust their workflow based off real-time data.

Lean manufacturing can also be used to reduce inventory levels. Lean manufacturing seeks to eliminate waste from every step of the production cycle. Anything that doesn't add value to the product is considered waste. These are some of the most common types.

-

Overproduction

-

Inventory

-

Unnecessary packaging

-

Overstock materials

These ideas can help manufacturers improve efficiency and reduce costs.

Statistics

- According to the United Nations Industrial Development Organization (UNIDO), China is the top manufacturer worldwide by 2019 output, producing 28.7% of the total global manufacturing output, followed by the United States, Japan, Germany, and India.[52][53] (en.wikipedia.org)

- You can multiply the result by 100 to get the total percent of monthly overhead. (investopedia.com)

- (2:04) MTO is a production technique wherein products are customized according to customer specifications, and production only starts after an order is received. (oracle.com)

- [54][55] These are the top 50 countries by the total value of manufacturing output in US dollars for its noted year according to World Bank.[56] (en.wikipedia.org)

- In the United States, for example, manufacturing makes up 15% of the economic output. (twi-global.com)

External Links

How To

How to use 5S in Manufacturing to Increase Productivity

5S stands for "Sort", 'Set In Order", 'Standardize', & Separate>. Toyota Motor Corporation developed the 5S method in 1954. It allows companies to improve their work environment, thereby achieving greater efficiency.

The idea behind standardizing production processes is to make them repeatable and measurable. It means tasks like cleaning, sorting or packing, labeling, and storing are done every day. These actions allow workers to perform their job more efficiently, knowing what to expect.

Implementing 5S involves five steps: Sort, Set in Order, Standardize Separate, Store, and Each step requires a different action, which increases efficiency. For example, when you sort things, you make them easy to find later. You arrange items by placing them in an order. You then organize your inventory in groups. Finally, label all containers correctly.

This requires employees to critically evaluate how they work. Employees must be able to see why they do what they do and find a way to achieve them without having to rely on their old methods. They must learn new skills and techniques in order to implement the 5S system.

The 5S Method not only improves efficiency, but it also helps employees to be more productive and happier. They feel more motivated to work towards achieving greater efficiency as they see the results.