Management of your supply network is critical to your business's success. Your goal is to increase efficiency, decrease costs, and improve customer service. Management of your supply chain will not only increase revenues but also create a competitive advantage on the market. Eight of ten companies have higher revenue growth than the industry average because they have a strong supply chains management program.

To manage your supply chain, you need to keep track of the location of your inventory and monitor its status. You should also know how many of your products you have, their prices and the lead time.

The supply chain is an interdependent network of people, organizations, technologies, and resources that work together to produce, transport, and deliver goods and services. This network allows organizations produce and deliver goods better and faster. It also reduces production and purchasing costs. It is crucial to the production, delivery, and use of health care products and electronics.

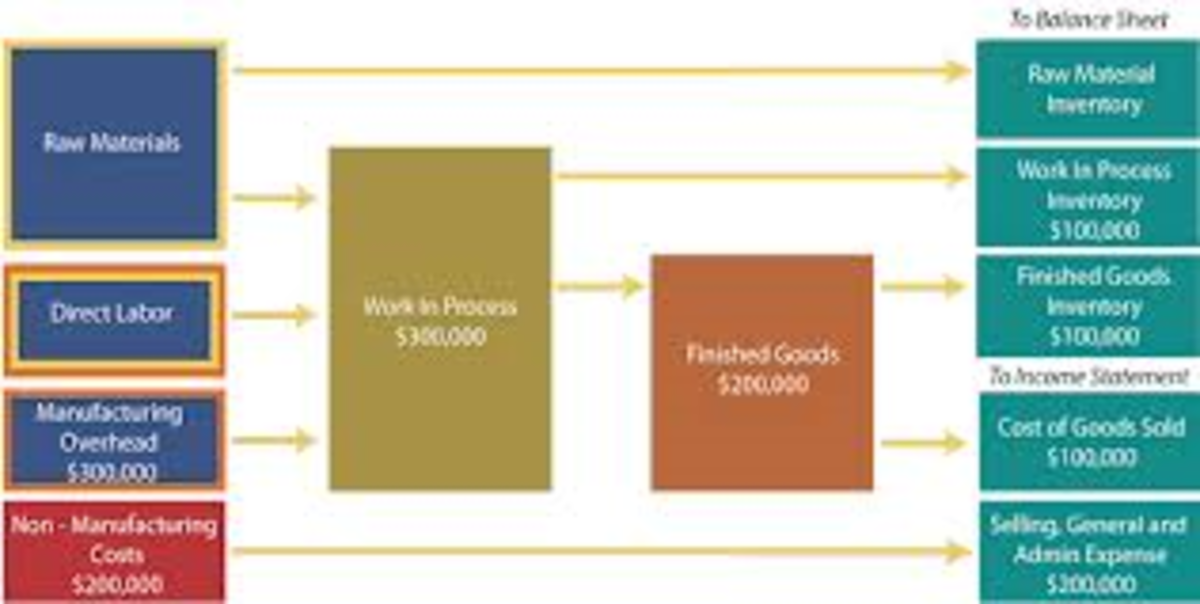

Supply chain management is about the design and implementation processes that get goods from raw materials up to the end consumer. It includes coordination of multiple activities, such as sales, marketing and production. It also involves a system that manages returns for defective products.

Supply chain complexity increases as global competition rises. This is due to part price fluctuations and offshoring as well as talent attrition. You may also have multiple suppliers to your organization, which can increase redundancy in your supply chains.

Supply chain management can involve many departments within your business, such as finance, sales, operations manufacturing and R&D.

You need to be proficient in each of the five components of supply chain management to manage your supply chain effectively. These elements include design and management of your supply network, selection of suppliers, management of supplier relationships, design of inventory management, coordination of supply chain logistics, and coordination.

Designing your supply chain plan requires the creation of a detailed plan. This plan outlines how your company will implement the supply chains strategy. It also includes a breakdown of the steps involved in achieving the plan. You may decide that you want to outsource manufacturing. This would include packaging and distribution. You may also need to inspect the finished products and collect payment from customers.

The design of your supply chain plan should also address the management of your supplier relationships. A vendor with a track record of timely delivery may be the best choice. You might also consider a flexible vendor to help you get emergency supplies when needed.

Supply chain management can also reduce the amount of wear and tear on your equipment. It can help you stay in touch with your customers and reduce quality issues.

FAQ

What is the difference between manufacturing and logistics

Manufacturing refers the process of producing goods from raw materials through machines and processes. Logistics is the management of all aspects of supply chain activities, including procurement, production planning, distribution, warehousing, inventory control, transportation, and customer service. As a broad term, manufacturing and logistics often refer to both the creation and delivery of products.

What is the role of a logistics manager

Logistics managers ensure that goods arrive on time and are unharmed. This is done through his/her expertise and knowledge about the company's product range. He/she also needs to ensure adequate stock to meet demand.

What is it like to manage a logistics company?

A successful logistics business requires a lot more than just knowledge. To communicate effectively with clients and suppliers, you must be able to communicate well. You must be able analyze data and draw out conclusions. You need to be able work under pressure and manage stressful situations. You need to be innovative and creative to come up with new ways to increase efficiency. Strong leadership qualities are essential to motivate your team and help them achieve their organizational goals.

You must be organized to meet tight deadlines.

How can we increase manufacturing efficiency?

First, we need to identify which factors are most critical in affecting production times. We then need to figure out how to improve these variables. If you aren't sure where to begin, think about the factors that have the greatest impact on production time. Once you have identified them, it is time to identify solutions.

What is the difference between Production Planning, Scheduling and Production Planning?

Production Planning (PP), also known as forecasting and identifying production capacities, is the process that determines what product needs to be produced at any particular time. This can be done by forecasting demand and identifying production capabilities.

Scheduling is the process that assigns dates to tasks so they can get completed within a given timeframe.

Statistics

- According to the United Nations Industrial Development Organization (UNIDO), China is the top manufacturer worldwide by 2019 output, producing 28.7% of the total global manufacturing output, followed by the United States, Japan, Germany, and India.[52][53] (en.wikipedia.org)

- (2:04) MTO is a production technique wherein products are customized according to customer specifications, and production only starts after an order is received. (oracle.com)

- Job #1 is delivering the ordered product according to specifications: color, size, brand, and quantity. (netsuite.com)

- In 2021, an estimated 12.1 million Americans work in the manufacturing sector.6 (investopedia.com)

- [54][55] These are the top 50 countries by the total value of manufacturing output in US dollars for its noted year according to World Bank.[56] (en.wikipedia.org)

External Links

How To

Six Sigma and Manufacturing

Six Sigma is "the application statistical process control (SPC), techniques for continuous improvement." Motorola's Quality Improvement Department in Tokyo, Japan developed Six Sigma in 1986. Six Sigma's core idea is to improve the quality of processes by standardizing and eliminating defects. In recent years, many companies have adopted this method because they believe there is no such thing as perfect products or services. Six Sigma's primary goal is to reduce variation from the average value of production. This means that if you take a sample of your product, then measure its performance against the average, you can find out what percentage of the time the process deviates from the norm. If there is a significant deviation from the norm, you will know that something needs to change.

The first step toward implementing Six Sigma is understanding how variability works in your business. Once you have a good understanding of the basics, you can identify potential sources of variation. These variations can also be classified as random or systematic. Random variations occur when people make mistakes; systematic ones are caused by factors outside the process itself. You could consider random variations if some widgets fall off the assembly lines. But if you notice that every widget you make falls apart at the exact same place each time, this would indicate that there is a problem.

Once you've identified the problem areas you need to find solutions. The solution could involve changing how you do things, or redesigning your entire process. Once you have implemented the changes, it is important to test them again to ensure they work. If they didn't work, then you'll need to go back to the drawing board and come up with another plan.